ADDITIONAL SERVICES

Edit Content

Rumbling

This process involves placing the metal parts in a large container with differing media liquids and vibrating at a high rate over a long period of time.

This process smooths and deburrs the parts leaving a uniform finish. This works well for batch orders and parts that are handled manually leaving smooth to touch edges.

Materials that we can rumble:

- Stainless steel

- Aluminium

- Brass

- Copper

Maximum part size 200 mm x 150 mm, but will depend on part.

Edit Content

Linishing and Cross Belting

We have various methods of linishing from a hand held to a hand fed mechanical linisher which deals with larger sheet material (1100 mm max width). This process deburrs, removes slag and small scratches and can also grain material (material dependent).

Cross belting deburrs and softens edges but is not as harsh as linishing. But leaves a uniform finish. This is material and size dependent. This may incur an additional charge.

Materials we can cross belt:

- Milled stainless steel

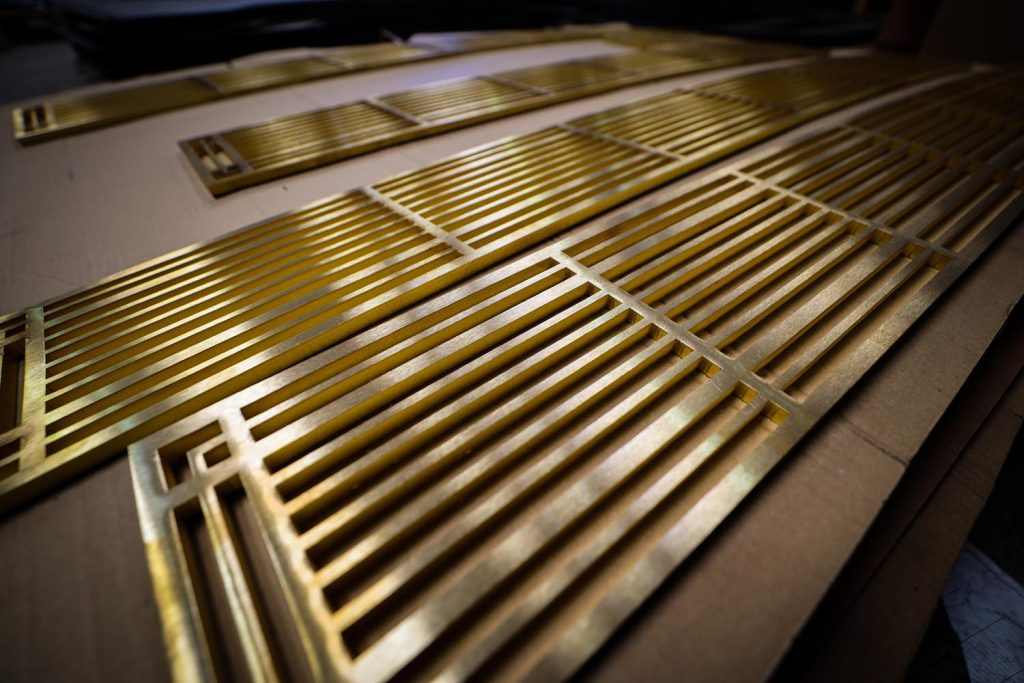

- Brass

- Copper

- Aluminium

Materials we can linish:

- Milled stainless steel

- Brass

- Copper

- Aluminium (This cannot be folded after linishing)

Edit Content

Vapour Blasting

This process blasts micro media via compressed air and water at the parts in a closed system cabinet. This blasts and degreases parts and leaves a soft finish appearance and can rejuvenate old parts.

This is material and size dependent. This is an additional chargeable service.

Materials we can vapour blast:

- Stainless steel

- Brass

- Copper

- Aluminium

- Mild steel

Maximum size 500 mm x 500 mm