Planters: By forming sheet metal, you can create unique planters that really enhance the look of gardens, parks, and outdoor areas.

Frames: Manufacture frames designed for a range of uses, including frames for photographs, window structures, and support frameworks for buildings and machinery.

Enclosures: Custom made covers and surrounds for electrical equipment, control panels, and industrial machinery. These enclosures provide protection and housing for sensitive components.

Facades: Create architectural facades for buildings. By bending sheet metal, unique and visually appealing facades can be fabricated, adding character and style to structures.

Guttering: Produce custom shaped guttering systems for residential and commercial buildings. By bending sheet metal, guttering components can be formed to efficiently channel water.

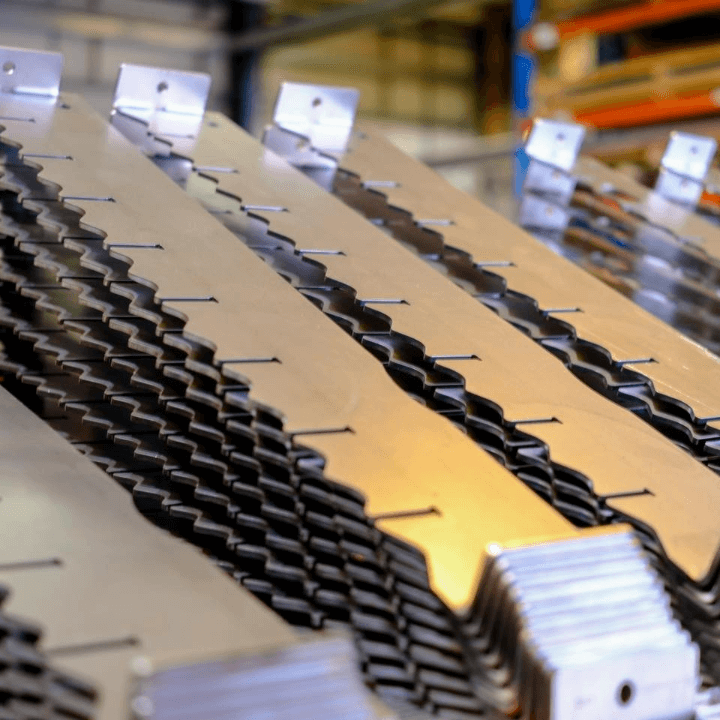

Channel, Angle, and Flashings: We can press various metal profiles, to create bespoke channels, angles, and flashings. These components are widely used in construction, manufacturing, and other industries.

Brackets: Manufacture brackets for mounting and supporting components in different applications, such as shelving, machinery, and furniture.

Doors: Fabricating replacement doors for cabinets, enclosures, and other structures. By bending sheet metal, doors can be formed to provide access and security.

Drip Trays: Used to create drip trays for collecting and holding liquids in industrial settings, laboratories, and other environments.

Worktops: Manufacturing worktops for various industries, including kitchen countertops, laboratory workstations, and industrial workbenches.