Sheet Metal Cutting Services

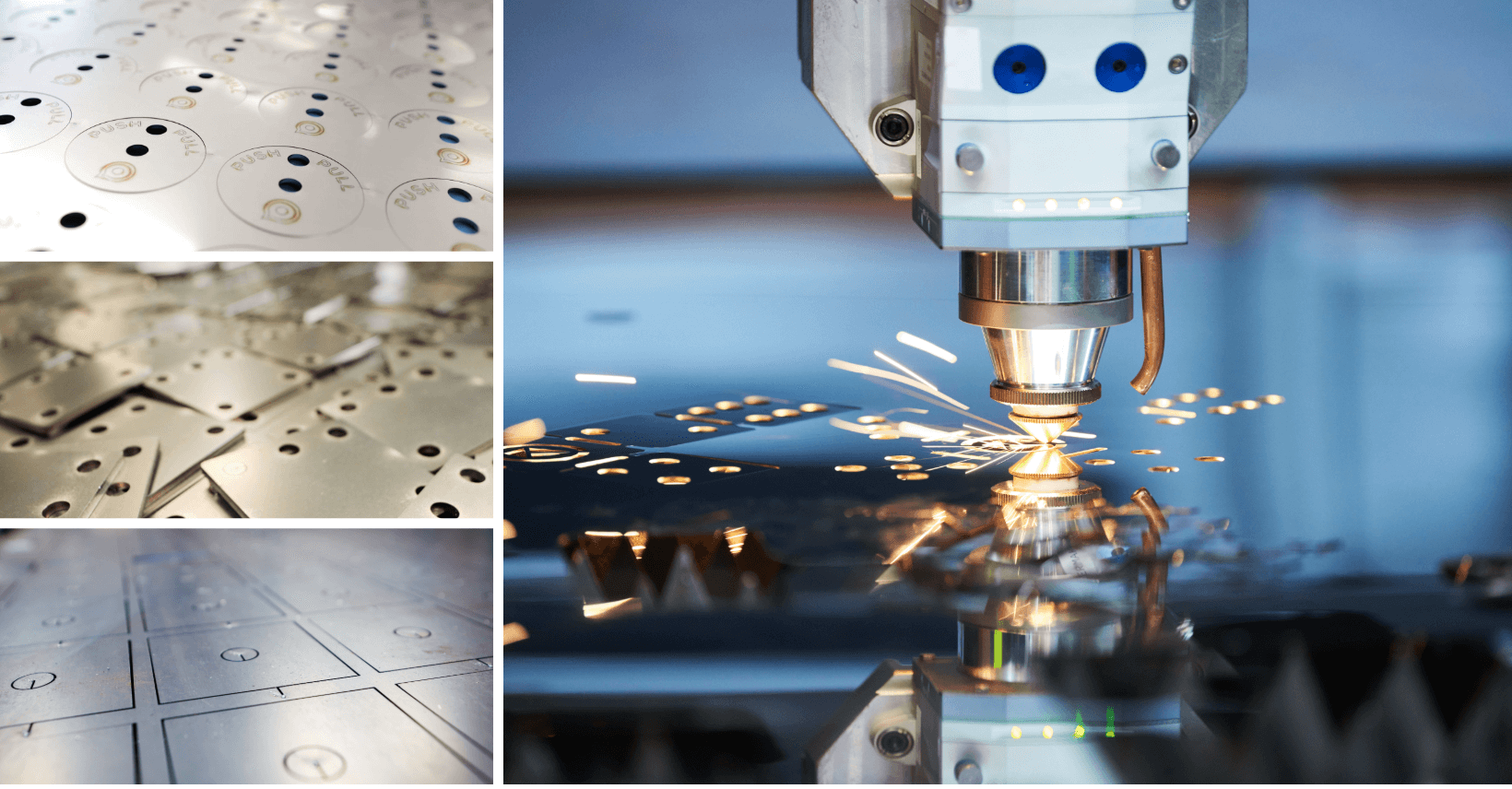

We laser cut metal sheets to size up to 30 mm thick.

Precision sheet metal cutting is at the very heart of our business. We are renowned for our excellent quality, cost-effectiveness and friendly service.

We offer 2 options for sheet metal cutting: fibre laser cutting and HD plasma cutting. These options are available in a range of sheet metals and thicknesses, including carbon steel/mild steel, stainless steel, high-strength steels, cor-ten/weathering steel as well as non-ferrous materials such as aluminium, brass, copper, and bronze. In addition, we offer a free issue metal laser cutting service. Metal plates and profiles thicker than 25 mm, we recommend using our HD plasma cutting service.

With no minimum order fees or quantity restrictions, ideal for low volume and prototyping, to cost-effective high volume production runs for manufacturing, LaserMaster has a sheet metal laser cutting service suitable for everyone.

Need your order urgently? Ask about our Fast Track express laser cutting service!

If your looking for custom cut metal profiles such as washers, spacers, flanges, discs, or other simple profiles? Take a look at our online Easy Order System.

Friendly Service

Our team is experienced, efficient and professional but above all easy to talk to, we are happy to answer any questions you have.

Competitive Pricing

We have the capability to operate 24 hours a day, 7 days a week, allowing us to offer an express turnaround and high volumes.

Nationwide Delivery

We ship completed orders using a next day courier and pallet service, ensuring the quickest lead time from quote to delivery.

We Laser Cut Sheet Metal to All Sizes

Fibre laser cutting offers remarkable economy, precision, and high-quality profiles.

Standard Stock of Sheet Metal Usually Available For Express Laser Cutting

| Material | Common Thicknesses Available For Fast Track Laser Cutting |

|

Aluminium 5251/5083 |

1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10mm, 12 mm, 15 mm, 20 mm |

|

Stainless Steel 304/316

|

0.5 mm, 0.9 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm Brushed (DP1) and Mirror Finish (MP1) up to 6 mm thick. |

| Mild Steel CR4/S275 |

0.9 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 20 mm |

| Copper |

0.7 mm, 0.9 mm, 1.2 mm, 1.5 mm, 2 mm, 3 mm, 4 mm |

| Brass |

0.55 mm, 0.9 mm, 1.2 mm, 1.5 mm, 2 mm, 3 mm, 4 mm |

Fast Track, Express Sheet Metal Cut to Size

Need your laser cutting orders done even faster? Try our Fast Track Laser Cutting Service! While our standard lead times usually take 5-7 working days, we understand that sometimes you have urgent requirements. That's why we offer this special service for super urgent orders. Simply place your order before 1 pm, and if we have the metal available, we'll laser cut and ship it the following working day. With our next working day dispatch service, you can have the parts delivered to you in just 2 working days, provided the courier service goes smoothly. Slots are limited for this service so please speak to one of sales team who will be able to advise on availability.

Tips on Obtaining A Prompt and Precise Sheet Metal Cutting Quote

We aim to quote within 24 hours, below are a few tips to enable us to quote for laser cutting more efficiently!

1. Supply either DXF or DWG 2D file formats, ideally, with one drawing per file, If all drawings are submitted in one file, don't include multiples of the same part, just include 1 off and indicate the quantity required for that part. Keep file names under 35 characters.

2. Only include the cut path of the part(s), without any borders, side views, but fold and etch lines can remain. Include dimension notes for verification purposes.

3. Make sure that the parts have no open contours. Scale and export the parts at their true size in mm, maintaining a 1:1 ratio.

4. Connect shapes and text using bridges to retain the centres of letters like R, A, Q. Convert all text to shapes/outlines.

5. Verify that the files are error-free and properly saved before sending.

6. Remove any Z-coordinates from the files.

7. Include any additional specifications and requirements such as folding, countersinking, tapping, etching or deburring in an accompanying PDF.

8. Remember thickness, material and quantity! Always Include as much information as possible in your initial enquiry.

The Benefits and Drawbacks of Sheet Metal Laser Cutting

Fibre laser cutting for sheet metal is a highly efficient, precise, and super-fast method of cutting metal sheets using a laser beam. This technology has revolutionised the manufacturing industry by offering numerous advantages over traditional cutting methods such as plasma and Co2 laser cutting. However, like any other technology and methods of cutting sheet metal, fibre laser cutting also has its limitations and disadvantages.

Here we will explain some advantages and disadvantages of sheet metal cutting using a fibre optic laser cutting.

The Benefits

Precision: One of the biggest advantages of sheet metal laser cutting is its exceptional precision. Fibre laser cutting machines can achieve a high level of accuracy and precision, allowing for intricate and complex designs to be cut with ease. This precision ensures that the final product meets the specifications and results in high-quality parts and profiles.

Versatility: Fibre laser cutting is a versatile process that can be used to cut a wider range of materials and greater thickness than Co2 laser cutters, including stainless steel & aluminium as well as highly reflective material that were not suitable for Co2 laser cutters such as copper, brass, and bronze. This versatility makes it an ideal choice for various industries, such as automotive, marine, renewable energy, electronics, and architecture.

Speed: Fibre laser cutting is a process compared to traditional cutting methods. Fibre lasers are super-fast, can cut through the metal sheet quickly and efficiently, reducing production time and increasing productivity. This speed advantage is particularly beneficial for large-scale manufacturing operations and urgent client requirements and express next day cutting services.

Minimal Material Waste: Unlike cutting methods such as guillotining and shearing, fibre Laser cutting is a non-contact process, which means there is no physical contact between the cutting tool and the material being cut. This results in minimal material waste, as the laser beam only removes the necessary material.

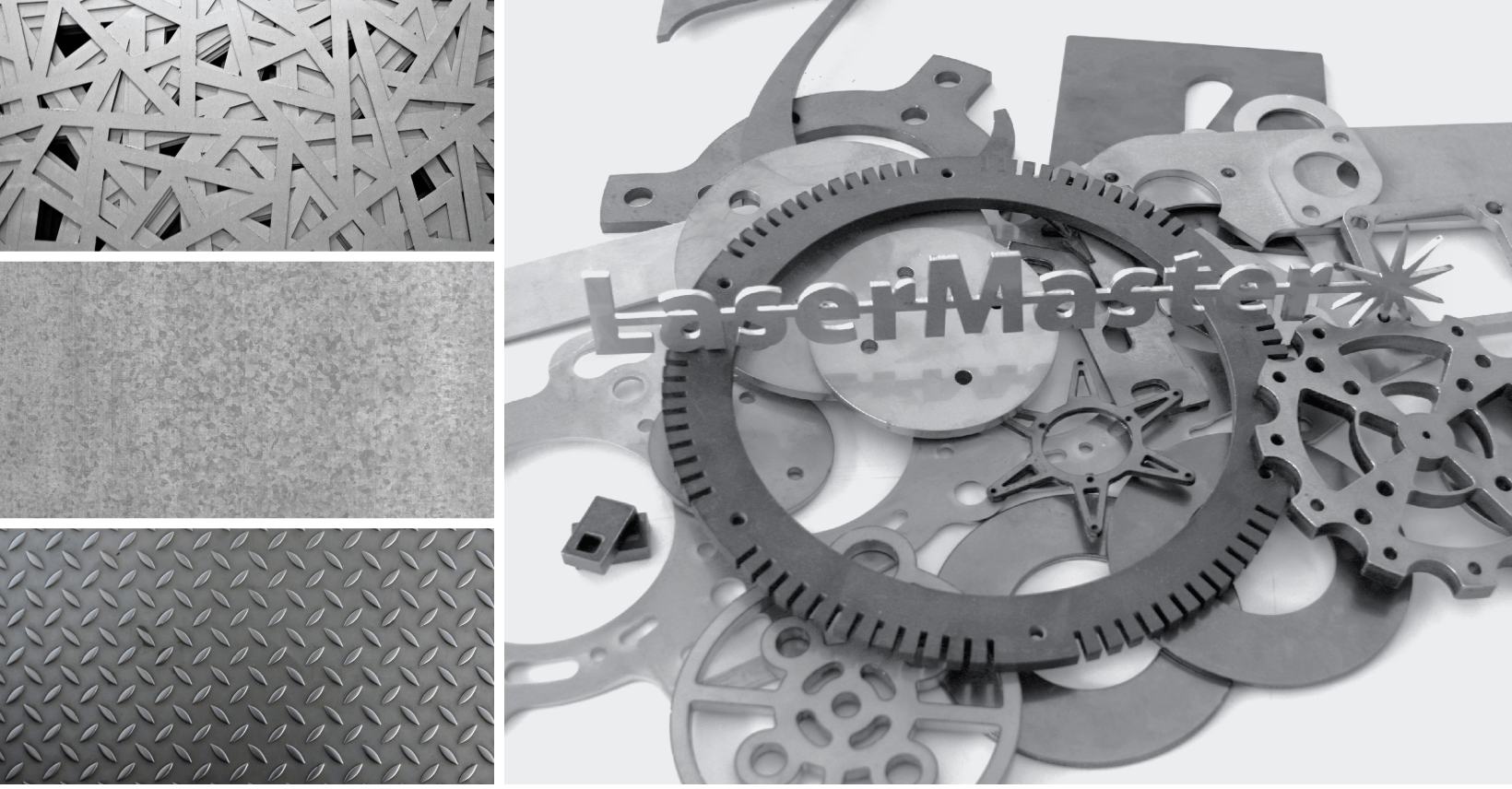

Complex Shapes and Designs: Fibre Laser cutting allows for the cutting of complex shapes and designs that would be difficult or impossible to achieve with traditional cutting methods such as plasma, and guillotine metalworking machines. The laser beam can follow intricate patterns and designs, enabling the production of highly detailed and customised profiles in sheet metal.

The Drawbacks

Material Limitations: While sheet metal fibre laser cutting is versatile, there are materials that are not suitable for this cutting method. For example, leather, wood, plywood, MDF, carbon fibre, cardboard, paper, plastics, textiles, acrylic and composite materials cannot be cut on a fibre laser cutting machine. Fibre lasers are designed for cutting sheet metal, with the exception of silver, which due to the highly reflective properties is not a metal suitable for this type of cutting process.

Heat Affected Zone: Laser cutting generates heat, which can result in a heat-affected zone (HAZ) around the cut edges. This HAZ may cause changes in the material properties, such as hardness and strength. The melting and subsequent cooling of the material changes the material structure. This effect is more obvious in mild/carbon steel cutting where oxygen is used as the cutting gas. The interaction of oxygen with the heated metal causes a reaction that heats the material to a greater temperature.

Blemishes and Scratches: Laser cut components will possibly need further finishing to ensure they are ‘ready for use’ or to achieve a uniform appearance. It is common for laser cut items to have blemishes/scuffs/scratches, primarily on the back face of the profile. There are two reasons for this damage to occur and both are caused by the laser cutting bed. Consisting of parallel rows of ‘pointed’ copper slats spaced 50 mm apart, when the laser beam comes into contact with a slat then splatter (Flashback) is deposited onto the reverse face of the profile. The second is caused by loading and unloading the sheet. The slats are designed in a way to minimise contact with the bottom of the sheet, thereby reducing interference with the ejected material while still offering adequate support to the sheet during cutting.

Lead-ins/Tagging and Pips: A Lead-in is where the laser first pierces the material to start (lead in) cutting the design. The laser almost finishes the cut at this same point, but not quite, this is intentional, leaving a very small uncut section, commonly called a tag , the tag plays a crucial role, keeping the part and its cut-out sections in place and attached to the sheet so they do not fall into the waste collection bins beneath the laser cutting bed. Additionally, it helps to prevent the part from shifting or tipping during the cutting process Any external or internal cut on a part, whether straight or curved, usually needs its own lead-in. When the part is removed from the sheet, the tag is ‘snapped/broken,’ leaving behind a small protrusion often called a 'pip or tag' on the cut edge(s) of the laser cut profile.

Distortion, Warping, Bowing and Flatness: Laser cut parts can experience warping or bending while being cut. The intense heat produced during the laser cutting process can cause certain areas of the material to heat up more than others. As the material cools at different speeds, it can lead to uneven contraction, causing warping, bowing and flatness issues. Additionally, the more intricate and detailed the design, the higher the likelihood of uneven expansion and contraction, which can ultimately impact the flatness of the final product.

Conclusion

Sheet metal laser cutting has numerous advantages, including precision, accuracy, versatility, speed, minimal material waste, and the ability to create complex shapes and designs and is very economical. However, it also has its limitations including some material and thickness restrictions, and the potential for a heat-affected zone. Despite these disadvantages, laser cutting is the perfect sheet metal cutting solution in the manufacturing industry due to its overall efficiency, quality, accuracy, speed, and cost effectiveness.

Frequently Asked Questions

If you can't find the answer, simply pop an email to sales@lasermaster.co.uk

Do you have a minimum order charge or quantity for sheet metal cutting?

We don't have any minimum order quantity or minimum order fee. Sheet metal cutting prices are determined by various factors, quantity, cutting time, labour and not just material usage. Typically, prices will begin at approximately £25.00 plus VAT. Or check out our online ordering system for simply shaped laser cut profiles, this way you share costs with other orders placed.

What are the best files to send to obtain a quotation?

1:1 in mm DWG and or DXF are perfect and allow us to quote quicker, these files can be imported directly into our quoting software. For simple items we can work from pencil sketches, PDF or Jpegs providing all the relevant dimensions are noted on the drawing to enable us to draw the item in CAD software. For more complicated and unique designs, we can sometimes convert PDF and jpegs. jpegs need to be high resolution and only be drawn with a hairline and contain no fill. Some software like sketch up and adobe illustrator do allow you to export as either DXF or DWG.

Can you give me a ball park price for sheet metal cutting over the phone?

No sadly not, sheet metal cutting costs are based on many factors and are not priced solely on material size. We will need all the information in an email to be able to price accurately.

How can I pay if I want to proceed with a quotation?

You can make payments using debit/credit cards by calling 01209 821 902 or through Bacs (bank transfer) please request a proforma invoice.

Can I order a sample?

Sure, when placing a large order for laser cutting we can offer a sample created from your artwork for you to review. There is a fee for this service due to the setup and laser time required.

The cost typically begins at £25.00 + vat, varying based on the sample size, and includes delivery if needed. If you decide to move forward with the bulk order, a portion of this payment will be credited towards the total quantity ordered.

What if I have an urgent sheet metal cutting order?

We have a special service called Fast Track Cutting, which offers express laser cutting for an extra £25.00 Plus VAT. If you make the payment by 1pm (Mon-Fri), we will cut your order (subject to material stock availability) and ship it the next working day using a next working day courier service. Please note that while we strive to deliver your items the next day, we cannot guarantee it due to any unforeseen circumstances with the courier. It's important to mention that the Fast Track fee is only for the express cutting of your item(s) and does not form any part of the shipping process.

How long will my order take to process?

Our typical processing time for laser cutting orders is 5-7 working days from payment. Please remember that this timeframe may change based on our current stock and capacity at the point of order. Additional post laser cutting processes such as folding, countersinking, or tapping, could take an additional 1-4 days depending on quantities. The estimated lead time will be provided when you receive a quote.

Feel free to talk to us about your lead times, and we will always do our best to accommodate. The exact lead time will depend on factors such as quantity and material stock availability.

For urgent orders, we also provide a fast track express laser cutting service.

My quote seems expensive for just a small piece of metal. How can I reduce the cost?

If your looking for a small quantity? Check out the online easy order to see if it meets your needs! Here your share a bulk of the costs with other orders placed online.

Alternatively to lower unit costs, consider increasing the quantity needed. Laser cutting depends on various factors, such as sheet loading time, which remains constant whether cutting 1 or 1000 pieces.

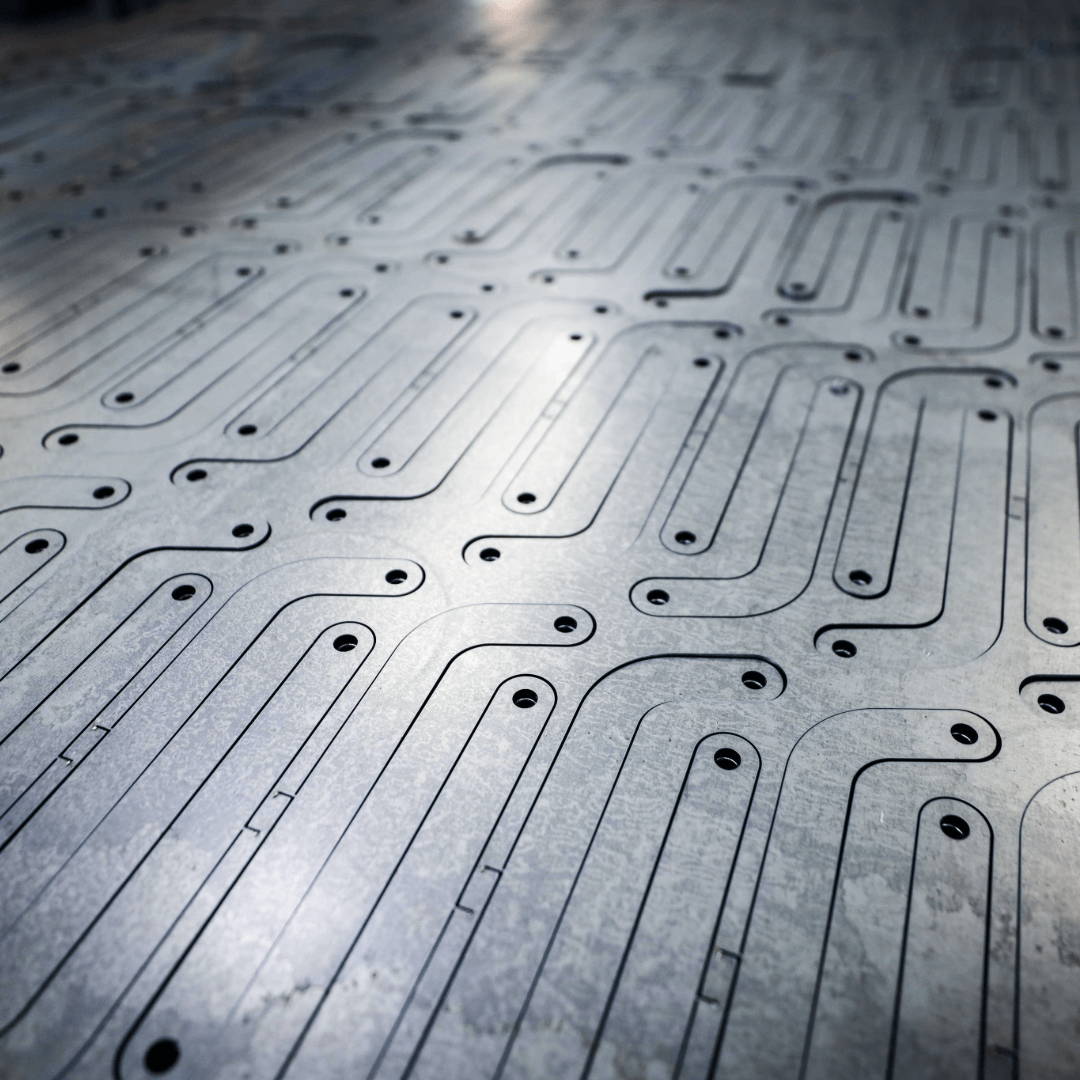

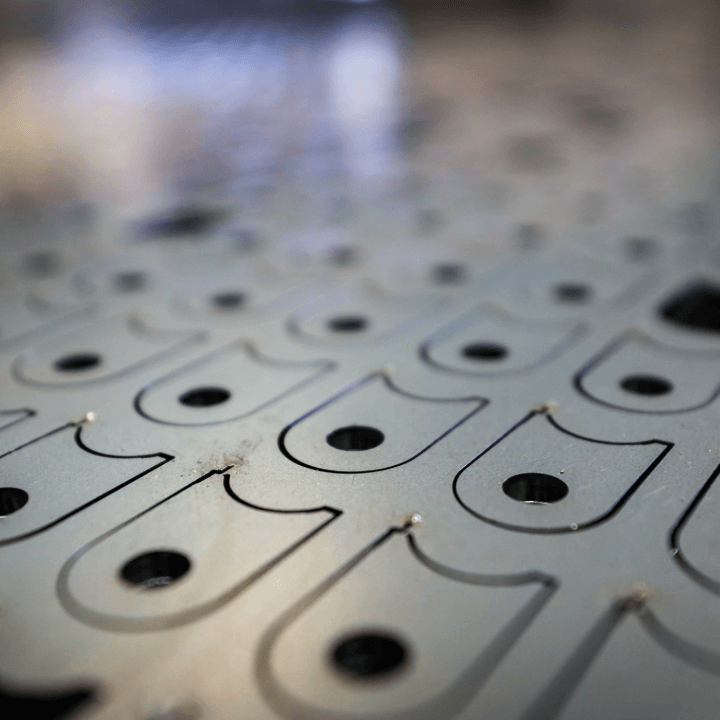

Examples of Sheet Metal Cutting

Contact Information

sales@lasermaster.co.uk+441209821902United Downs Industrial Park,St Day, Redruth, Cornwall

TR16 5HY